Solar mounting system is a supporting structure,which are fixed by the solar modules of a certain direction, arrangement and spacing , in combination with the geography, climate and solar resource conditions of the construction site, to maximize the power output of the photovoltaic power generation system. It is usually made of carbon steel structure or aluminum alloy structure, or a mixture of both.

Material of solar mounting system covering:

The raw material of solar mounting system is always using aluminum alloy AL 6005-t5, SUS304 stainless steel or hop dip galvanized Q235B carbon steel for production. Compared with cold galvanized steel sheet, other material are more suitable for outdoor usage, especially in island and rainy countries.During producing process, the derusted steel parts are immersed in the molten zinc at about 500 ℃, so that the zinc layer can be attached to the surface of steel members, so as to achieve the purpose of anti-corrosion. It is an effective metal anti-corrosion method,to ensure that the solar mounting system can be used for a long time under strong sunlight and humid weather.

Key points for high quality solar mounting system:

◭Using new materials only.

Recycled materials are easy to cause surface rusty in a short time.

◭Using hop dip galvanized steel only for steel solar mounting bracket.

Cold galvanized steel sheet are easy to rust within one year (average coating thickness 8-10 micron). Hot dip galvanized steel is the best way to prevent rusting and maintain beautiful appearance for a long time.(average coating thickness 55 micron).

◭Additives.

Adding necessary sufficient zinc layer protection and antioxidant materials.

◭Test equipment.

Having necessary test equipment for antioxidant value.

At present, the most popular material in the market is aluminum alloy AL6005-T5 , because it has the following advantages

◭Light and soft:

The density of aluminum is about 1/3 of steel

◭Good strength:

The tensile strength of pure aluminum is 1/5 of low carbon steel, but its strength will increase greatly after heat treatment and alloying strengthening

◭Good corrosion resistance:

One of the characteristics of aluminum alloy is that a dense oxide film will be formed on the surface when contacting with air, which can prevent corrosion, so it has good corrosion resistance. If the "alumina membrane treatment method" is applied to it, it can comprehensively prevent corrosion

◭Good process-ability:

The aluminum alloy has good extrusion performance, and the secondary machining and bending processing are also easy to handle.

◭Easy regeneration:

Aluminum has low melting point, simple regeneration, and no pollution during waste disposal treatment, which is conducive to environmental protection and meet with the sustainable development strategy .

Advantages of solar panel aluminium structure compared with solar panel steel structure:

◭Saving installation time and labor cost.

Aluminum solar structure has higher machining accuracy ,much lighter weight,and parts have been high pre-assembly in factory to save 30% installation time.

◭Excellent duration.

With high class anti-corrosion protection,solar aluminium structure will have more than 20years duration lifetime and almost no need maintenance cost for outdoor using,but solar steel structure will have to be rewelded and repainted to keep its service life.

◭Affordable Price.

With reasonable price,price of aluminium solar panel brackets will not be very higher than steel solar structure ,only about 20~25% price difference.

◭High priced recycling.

Scrap aluminium can be sold at a high price after using,which about 40% purchase price of aluminium installation.but scrap steel will be worthless.

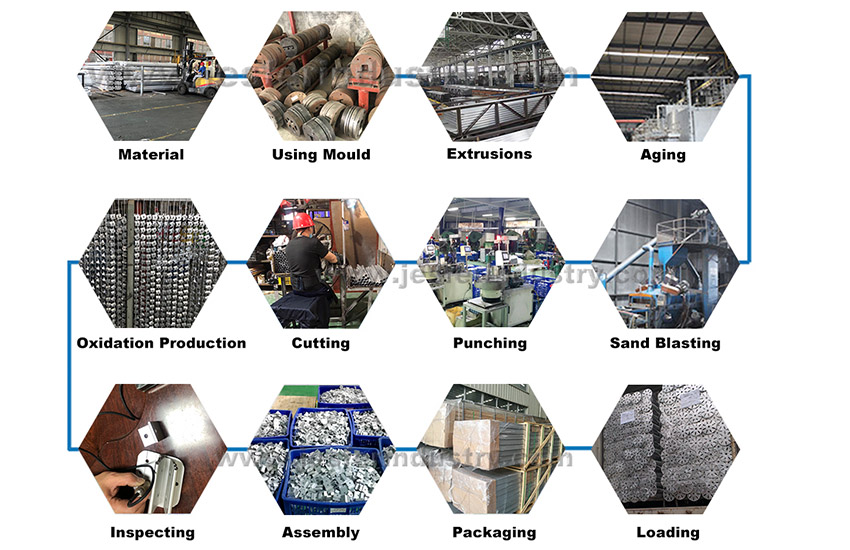

Manufacturing Process:

Customization of solar mounting system:

◭What is your solar panels dimension and power?__________mm Length,________mm Width,__________mm Thickness,__________Watt.

◭ As for the layout of solar panels for each little unit,how many pieces in a row and how many rows?______Nos.in a row,_______Rows .

◭How many pieces solar panel you want to install?total__________Pieces.

◭ how about solar panel install tilt angle and ground clearance?tilt angle______degree,height of panels lowest end off ground or roof floor:______mm.

◭ How is wind speed and snow load? Anti wind speed:_________m/s or _______km/h or_______mph ,snow load__________KN/m2.

◭ What is your foundation?ground screw or concrete block?

◭ How about material require?Aluminium alloy or galvanized steel?

◭ Pitched Roof type:tiles roof or metal roof or asphalt shingle roof? if your project is roof system,please provide the roof height and roof drawing.

◭ Ground type:flat roof solar mount or ground mount or carport mounting.

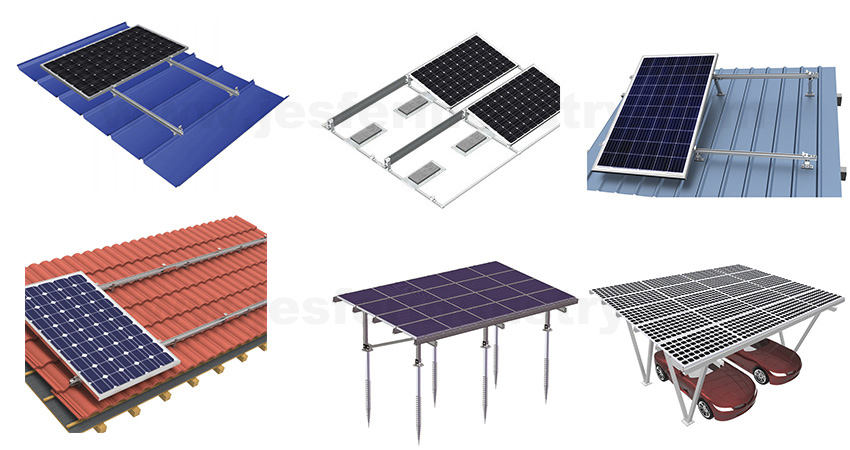

Application of solar mounting system:

◭ Metal roof

◭ Tiles roof

◭ Roman roof

◭ Flat concrete rooftop

◭ Open filed ground

◭ Commercial parking

◭ Home carport

◭ RV and Yacht

Order Process:

Sample Policy:

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.Or We can produce by your samples or technical drawings. We can build the molds and fixtures.

Trade Terms:

* FOB:Free On Board

* CIF:Cost, Insurance and Freight

* CFR:Cost And Freight

* DDU: delivered duty unpaid.(For most countries, DDU is available if clients have import license.)

* DDP:delivered duty paid (For most countries, DDP is available if clients with no import license.)

Terms of Payment:

* For regular order, we only work with T/T.

* TT 50% as a deposit,We'll show you the photos of cargo's packages before you pay the balance.

* For smaller order, we work with Western Union Bank charge to be with buyer.

Terms of Packing:

Generally, we pack our goods in brown cartons for small solar mounting components in short length and packed with wooden & iron pallet for solar beams or rails in long size.We can pack the goods in your brand packing box after receiving your authorization.

Available Transportation Ways:

* Ocean freight transport

* Air freight transport

* For small orders, sometimes could be delivered with courier services.

Delivery Time:

Generally, it will take15 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

A total of 1 pages

No. 109 HuanDeng North Road,Xiangan District, Xiamen City, Fujian Province, China

Email : info@jesferindustry.com